Multi-scale Hydrogeomecanics

Contacts:

► Eric Lefevre, technical manager - Tél. +33(0)3 72 74 45 67

► Laurent Schoumaker, technical manager - Tél. +33(0)3 72 74 45 51

► Dragan Grgic, scientific manager

Tél. +33(0)3 72 74 45 69

The platform in video

|

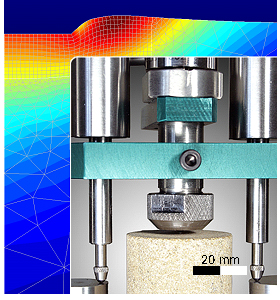

The objective is to characterise the hydro-mechanical behaviour of rocks with the help of laboratory tests and to apply these findings to the study of underground sites and reservoirs. The principle consists of applying various types of mechanical, thermal, hydrological and chemical stresses to a rock sample in order to reproduce conditions underground. We then develop behavioural models and perform numerical simulations based on the experimental data acquired. For example, we can study the mechanisms of failure of a cylindrical rock sample by compression under a mechanical press. During the compression test, we record the sample deformations and the induced microseismicity. The data collected then allow us to determine the fracturing conditions of the material. The strengths of this experimental platform reside in the coupling between experimental and numerical modelling to best reproduce the complexity of the subterranean environment. The ‘Multi-Scale Hydrogeomechanics’ team maintains two experimental facilities. The ‘Rock Mechanics’ laboratory is equipped with:

In addition, the ‘Transfer in Porous Media’ laboratory hosts:

an experimental room dedicated to the study of biological processes in porous media (e.g., biodegradation, bacterial growth).

|

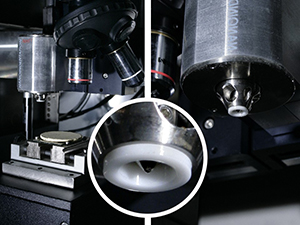

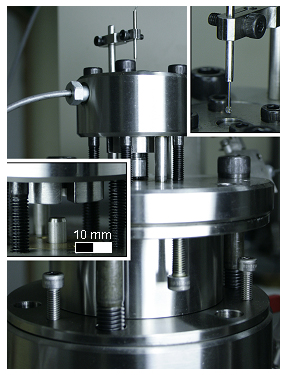

Nanoindentation experimental system

Microindentation testing (2D punch modelling)

Subcritical fracture propagation testing (double torsion)

Triaxial microcompression cell (+/- 1.5 mm displacement sensor and 500N force sensor) |

|

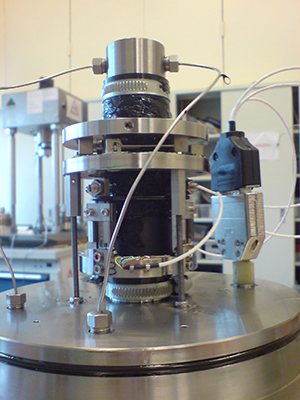

Cylindrical sample placed in a triaxial macro-compression cell |

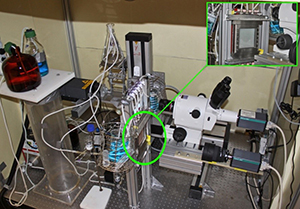

Use of optical imaging and microscopy to monitor transport of solutes in biofilms (experimental room dedicated to study of biological processes) |

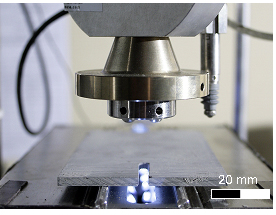

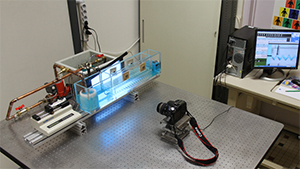

Laser-induced fluorescence system |

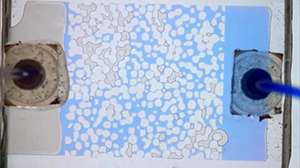

Imbibition experiments in a micromodel |

2D fracture model |